FEATURES

• No post cure (NPC)

• Pigmentable

• Serviceable over a wide

temperature range

COMPOSITION

• Silicone rubber

DESCRIPTION

Silastic® NPC-40 and NPC-80

Silicone Rubbers are designed

as no-post-cure, general-purpose

silicone rubbers. These silicone

rubbers can be compounded with

a variety of extending fillers or

blended with selected bases to fabricate

parts with other hardnesses

upon vulcanization. They are serviceable

over a wide temperature

range.

Typical properties are shown on

the next page.

HOW TO USE

Vulcanizing Agents

Silastic NPC-40 and NPC-80 Silicone

Rubbers require the addition of a

vulcanizing agent. T catalyst (2,4-dichlorobenzoyl

peroxide) is recommended

for hot air vulcanization.

V catalyst (2,5-bis[tert-butylperoxy]-

2,5-dimethylhexane) or D catalyst

(dicumyl peroxide) is recommended

for molding.

Compounding

Silastic NPC-40 and NPC-80 Silicone

Rubbers can be blended with other

bases and Silastic NPC-40 Silicone

Rubber can be extended with

fillers to modify the durometer of

the compounds. Further, Silastic

NPC-40 and NPC-80 Silicone

Rubbers can be pigmented to

almost any color shade desired.

Heat Stability

Addition of Silastic® HT-1 Modifier

(1 phr) or red iron oxide paste (3

phr) is recommended to improve

heat stability with Silastic NPC-40

and NPC-80 Silicone Rubbers.

Silastic HT-1 Modifier allows the

rubbers to be pigmented to almost

any color shade desired.

HANDLING

PRECAUTIONS

During vulcanization and oven curing,

vapors are given off that may

be harmful. Inhalation of vapors

should be avoided. Vulcanization

should be conducted in an area

that is properly ventilated.

PRODUCT SAFETY INFORMATION

REQUIRED FOR SAFE

USE IS NOT INCLUDED IN

THIS DOCUMENT. BEFORE HANDLING,

READ PRODUCT AND

MATERIAL SAFETY DATA SHEETS

AND CONTAINER LABELS

FOR SAFE USE, PHYSICAL AND

HEALTH HAZARD INFORMATION.

THE MATERIAL SAFETY

DATA SHEET IS AVAILABLE

FROM YOUR DOW CORNING

REPRESENTATIVE, OR

DISTRIBUTOR, OR BY CALLING

YOUR GLOBAL DOW CORNING

CONNECTION.

Product Information

Silicone

Rubbers Silastic® NPC-40 and

NPC-80 Silicone Rubbers

Silicone rubbers designed for no-post-cure general-purpose

applications

APPLICATIONS

• Molded, extruded, and calendered goods

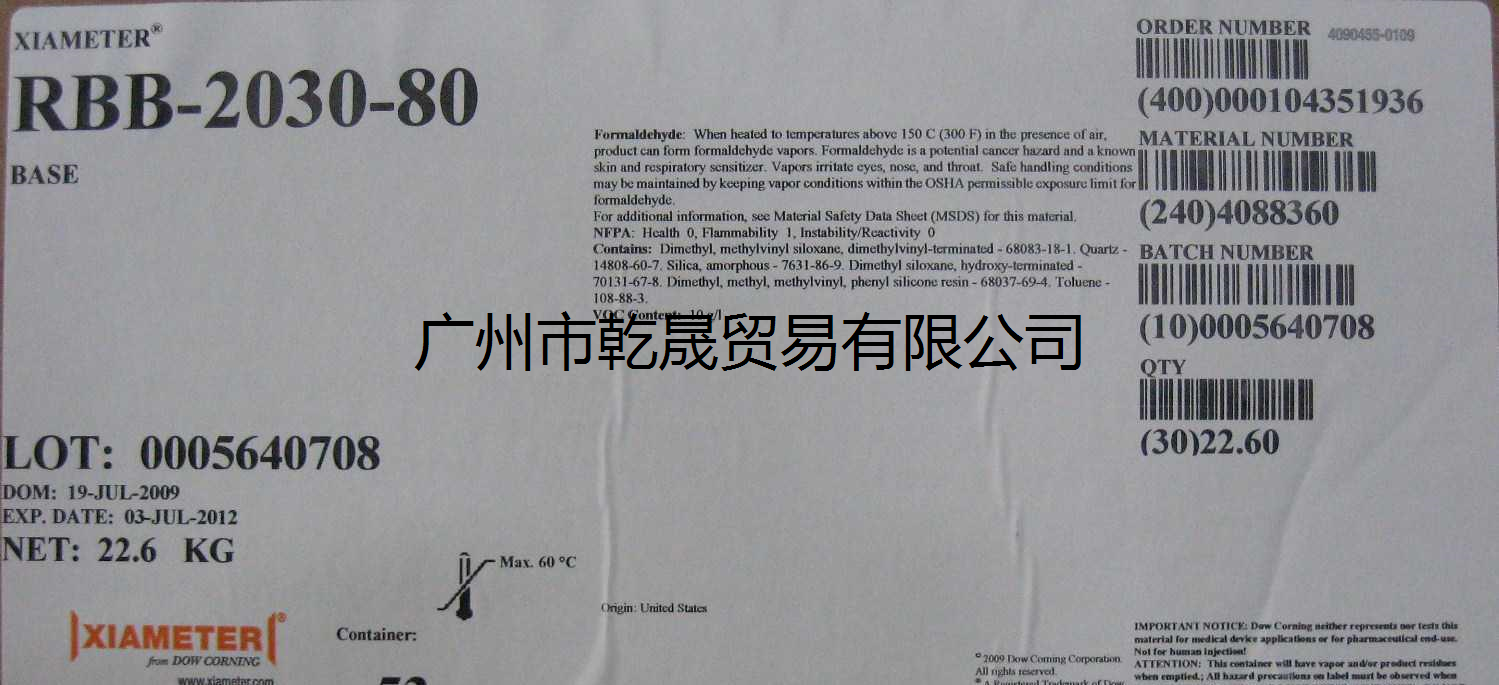

USABLE LIFE AND

STORAGE

When stored at or below 50°C

(122°F), Silastic NPC-40 and NPC-

80 Silicone Rubbers have a shelf

life of 36 months from date of

manufacture. Refer to product

packaging for “Use By” date.

PACKAGING

Silastic NPC-40 and NPC-80 Silicone

Rubbers are supplied in 22.7-kg

(50-lb) and 454-kg (1000-lb) boxes,

net weight.

It is recommended that incoming

inspection tests, as well as any

other tests deemed necessary for

the application, be performed to

confirm product identity and condition

upon arrival. Such tests may

or may not be performed as lot

acceptance tests.

LIMITATIONS

These products are neither tested

nor represented as suitable for

medical or pharmaceutical uses.

WARRANTY

INFORMATION—PLEASE

READ CAREFULLY

The information contained herein

is offered in good faith and is

believed to be accurate. However,

because conditions and methods

of use of our products are beyond

our control, this information

should not be used in substitution

for customer’s tests to ensure

that Dow Corning’s products are

safe, effective, and fully satisfactory

for the intended end use.

Dow Corning’s sole warranty

is that the product will meet the

Dow Corning sales specifications

in effect at the time of shipment.

Your exclusive remedy for breach

of such warranty is limited to

refund of purchase price or

replacement of any product shown

to be other than as warranted.

Dow Corning specifically disclaims

any other express of implied warranty

of fitness for a particular

purpose or merchantability. Unless

Dow Corning provides you with a

specific, duly signed endorsement

of fitness for use, Dow Corning

disclaims liability for any incidental

or consequential damages.

Suggestions of use shall not be

taken as inducements to infringe

any patent.

TYPICAL PROPERTIES1

Specification Writers: Please contact your local Dow Corning sales office or your Global Dow Corning Connection before

writing specifications on these products.

Silastic NPC-40 Silastic NPC-80

Formulations: Silicone Rubber Silicone Rubber

Silastic Silicone Rubber, parts 100 100

V Catalyst, 45% active, parts 1 1

Press Cured: minutes at °C (°F) 10/171 (340) 10/171 (340)

Method Test Unit Results

Appearance White, nearly opaque Beige, opaque

ASTM D 926 Plasticity mm x 100 (mils) 150 (59) 270 (108)

ASTM D 792 Specific Gravity at 23°C (73°F) 1.11 1.43

ASTM D 2240 Durometer Hardness, Shore A points 42 85

ASTM D 412 Tensile Strength MPa (psi) 7.2 (1050) 8.0 (1160)

ASTM D 412 Elongation % 575 90

ASTM D 412 Modulus at 100% Elongation MPa (psi) 0.8 (115) n/a

ASTM D 624 Tear Strength, Die B kN/m (ppi) 11 (65) 14 (80)

ASTM D 2632 Bashore Resilience % 67 53

ASTM D 2137 Brittle Point °C (°F) -73 (-99) -73 (-99)

1Properties were obtained using Corporate Test Methods (CTMs) on 2.0 ± 0.2 mm-thick (0.080 ± 0.008 in.) slabs. CTMs correspond to standard

ASTM tests in most instances. Copies of CTMs are available upon request.

Table I: Properties of Silastic NPC-40 Silicone Rubber and Silastic NPC-80 Silicone Rubber with Various Catalysts

Specification Writers: Please contact your local Dow Corning sales office or your Global Dow Corning Connection before

writing specifications on these products.

Formulations: Silastic NPC-40 Silicone Rubber Silastic NPC-80 Silicone Rubber

Silastic Silicone Rubber, parts 100.0 100.0 100.0 100.0 100.0 100.0

T Catalyst, 50% active, phr 1.0 — — 1.5 — —

D Catalyst, 40% active, phr — 1.3 — — 0.8 —

V Catalyst, 45% active, phr — — 1.0 — — 1.0

Press Cured: minutes at °C (°F) 5/116 (240) 10/160 (320) 10/171 (340) 5/116 (240) 10/160 (320) 10/171 (340)

Test Unit Results

Original Physical Properties1

Durometer Hardness, Shore A points 42 44 42 78 82 85

Tensile Strength MPa (psi) 7.6 (1100) 7.3 (1065) 7.9 (1140) 7.1 (1035) 7.4 (1080) 8.0 (1165)

Elongation % 550 555 595 160 130 85

Modulus at 100% Elongation MPa (psi) 0.8 (120) 0.8 (120) 0.8 (110) 5.6 (815) 6.3 (920) n/a

Tear Strength, Die B kN/m (ppi) 13 (75) 14 (80) 15 (85) 15 (85) 17 (95) 15 (85)

Compression Set, 22 hours

at 177°C (350°F) % 41 17 16 51 32 13

Circle Shrink % 2.2 3.4 3.7 1.4 2.2 2.4

1Properties were obtained using Corporate Test Methods (CTMs) on 2.0 mm-thick (0.080 in.) slabs, cured as shown. CTMs correspond to

standard ASTM tests in most instances. Copies of CTMs are available upon request.

Table II: Heat Resistance of Silastic NPC-40 Silicone Rubber/Silastic NPC-80 Silicone Rubber Blends

These values are not intended for use in preparing specifications.

Formulations:

Silastic NPC-40 Silicone Rubber, parts 100 75 50 25 0

Silastic NPC-80 Silicone Rubber, parts 0 25 50 75 100

Silastic HT-1 Modifier, phr 1 1 1 1 1

V Catalyst, 45% active, phr 1 1 1 1 1

Press Cured: minutes at °C (°F) 10/171 (340) 10/171 (340) 10/171 (340) 10/171 (340) 10/171 (340)

Test Unit Results

Original Properties1

Durometer Hardness, Shore A points 42 51 62 75 85

Tensile Strength MPa (psi) 7.7 (1110) 7.4 (1075) 7.5 (1090) 8.0 (1155) 8.6 (1245)

Elongation % 585 425 280 180 100

Modulus at 100% Elongation MPa (psi) 0.8 (110) 1.3 (190) 2.5 (365) 4.9 (715) 8.6 (1250)

Compression Set, 22 hours

at 177°C (350°F) % 14 11 10 10 11

Heat Aged, 70 hours at 225°C (437°F)

Durometer Hardness, Shore A points 37 49 62 78 87

Tensile Strength MPa (psi) 7.0 (1010) 7.3 (1065) 7.1 (1030) 7.2 (1045) 6.8 (990)

Elongation % 605 425 250 140 75

Modulus at 100% Elongation MPa (psi) 0.7 (95) 1.3 (190) 2.6 (380) 5.3 (775) n/a

Heat Aged, 168 hours at 260°C (500°F)

Durometer Hardness, Shore A points 44 59 71 84 91

Tensile Strength MPa (psi) 3.6 (525) 4.2 (605) 4.4 (635) 4.8 (690) 5.3 (770)

Elongation % 255 185 95 65 30

Modulus at 100% Elongation MPa (psi) 1.3 (185) 2.2 (315) n/a n/a n/a

1Properties were obtained using Corporate Test Methods (CTMs) on 2.0 mm-thick (0.080 in.) slabs, cured as shown. CTMs correspond to

您现在的位置是:

您现在的位置是: 双二四硫化剂

双二四硫化剂